Processing

The Production Flow Chart of Ductile Iron Pipes

1.Molten |

The raw materials are molten in electric induction furnace. The temperature and composition of the molten iron are monitored and controlled in the holding furnace. |

2.Desulfurizing, Spheroidizing and Inoculation Treatments |

The molten iron is treated with magnesium and become spheroidized. |

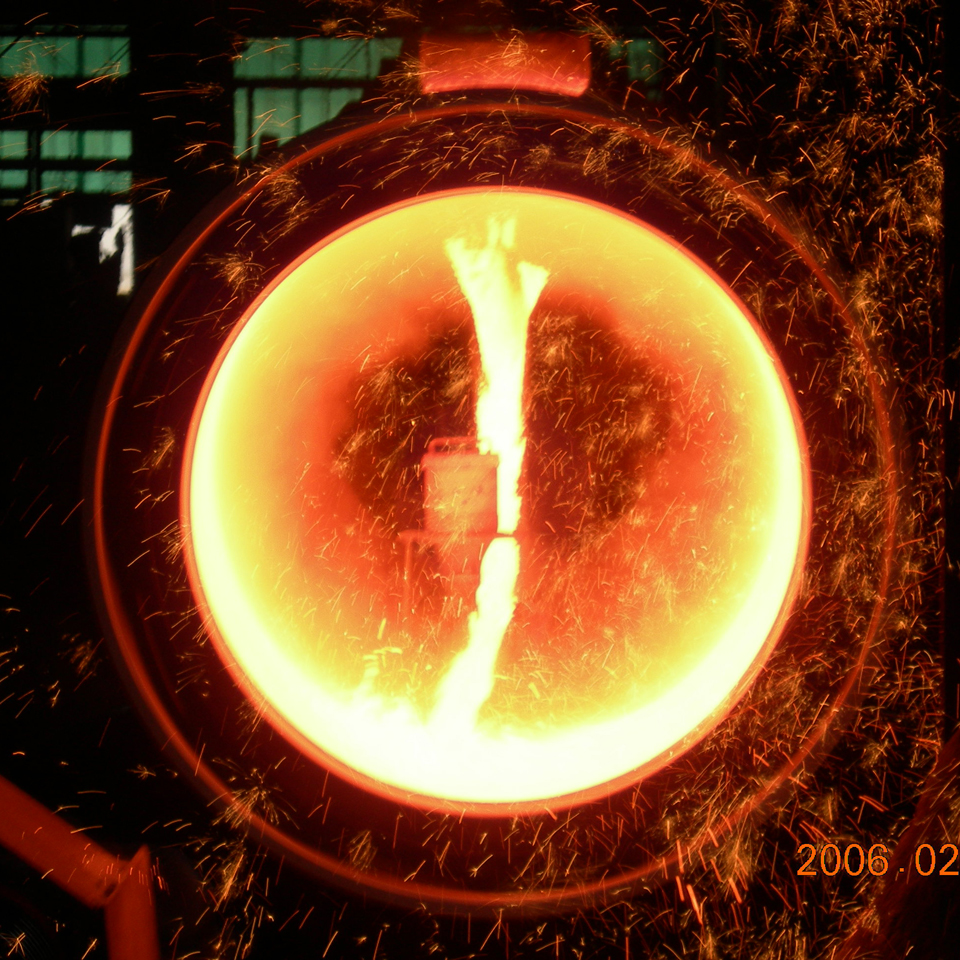

3.Centrifugal casting |

Two methods are applied in the centrifugal casting: one is metal mold water-cooling process, the other is wit-spray hot mold process. |

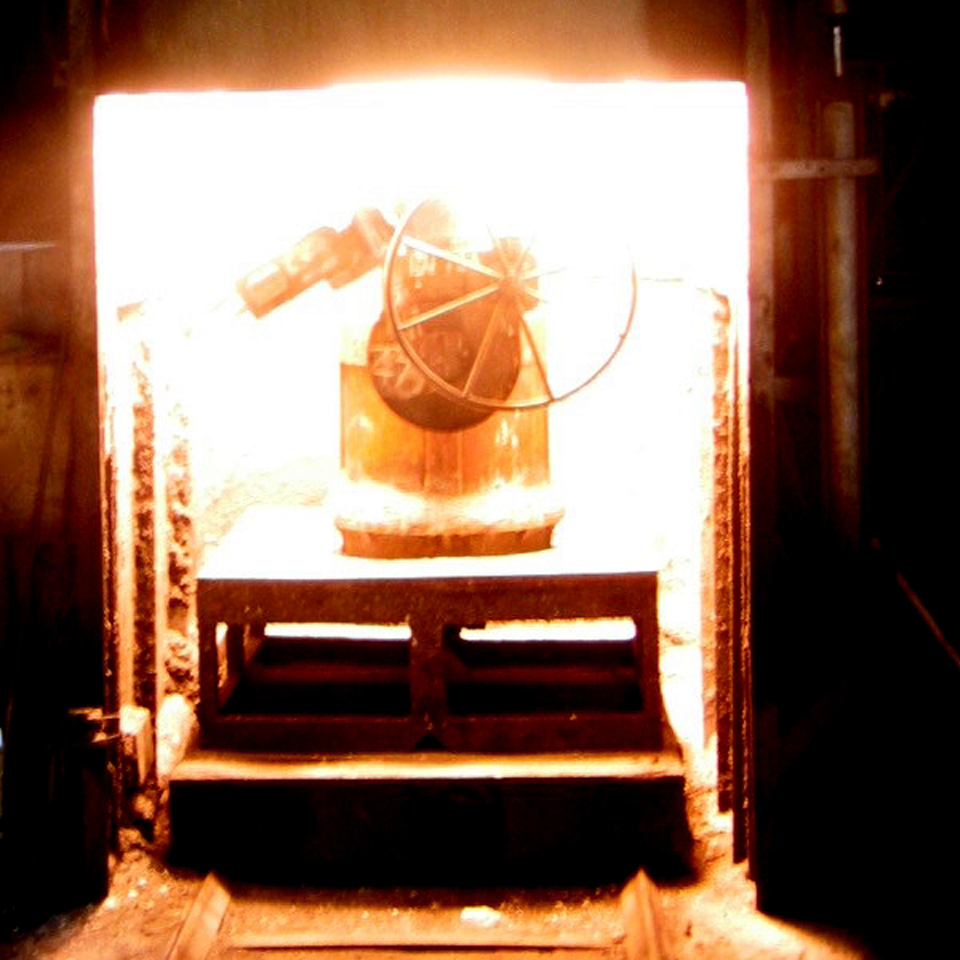

4.Continuous heat treatment |

After casting, the pipe is sent to the heat treatment furnace to change its metallographic structure. |

5.Test and inspection |

After mechanical processing, metallographic examination, flattening test, hydrostatic pressure test and scale inspection are applied. |

6.Inspection and Testing |

After inspection, the internal of pipe is applied with a cement mortar lining or epoxy powder coating. |

7.Lining, Coating and Final Inspection |

The outside of pip is applied with metallic zinc, on top of metallic zine, bitumen paint is applied. |

The Production Flow Chart of Ductile Iron Fittings

1.Molten |

The raw materials are molten in electric induction furnace. The temperature and composition of the molten iron are monitored and controlled in the holding furnace. |

2.Modeling and casting |

The molten iron is treated with magnesium and become spheroidized. |

3.Modeling and casting |

According to the size of fittings: Either furan resin sand molding method or cement molding method is applied. |

4.Spray cleaning and machining |

After the casting is taken out, the casting is sprayed and grounded, and then machine processed. |

5.Test and inspection |

After mechanical processing, metallographic examination, flattening test, hydrostatic pressure test and dimensional inspection are applied. |

| 6.After inspection, the internal surface of fitting is applied with epoxy powder coating. | |

|

7.The external surface of fitting is applied with metallic zinc and bitumen coating. |